Put Our Experience To Work For You

Our Services

Product Design

We create detailed and accurate 3D models, drawings and specifications that aid in the design and manufacturing of the mechanical products, parts and assemblies.

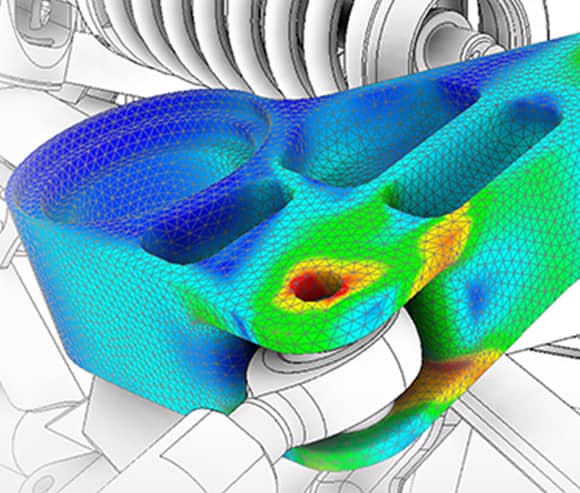

Analysis

Our engineers provide advanced analysis solutions and methods to simulate some of the toughest elements of product performance.

Rapid Prototyping

We cover all of your prototyping needs. We provide rapid prototypes, simple 3D printing, high-end appearance models, proof of concept models, functional models, and small batch production prototypes.

Manufacturing

We can provide the benefits of multi-axis machining and create complex shapes in a single set-up. Our tools mill away excess material, providing improvements and increased complexity over other CNC tools.

How SEALMAKER Works

The Science of Shear Activating Sealants

Flow patterns in different fluid flow situations are predictable.. The ratio of inertial forces to viscous forces quantifies the relationship of these two types of forces for given flow conditions. Simple fluid dynamics characterizes three different flow regimes; laminar, turbulent, and transitional flow. Laminar flow occurs where viscous forces are dominant, and is characterized by smooth, constant fluid motion. Turbulent flow occurs where inertial forces are dominant, and is characterized by flow having chaotic eddies, vortices and other instabilities. Very small changes to shape and surface roughness can result in very different flows. Transitional flow is the point that the fluid transitions from laminar to turbulent flow. Velocity and fluid rheology determine at precisely what point they will move from laminar, through transition, and finally into turbulent flow. By designing sealants that transition at a specific velocity or rate of shear allows us to control the activation.

What Actually Happens Inside a Leak Path

There is a flow of constant energy through any leaking system,and when fluid flows through a region of lower pressure it speeds up and vice versa. Bernoulli's principle states that "for an inviscid flow of a nonconducting fluid, an increase in the speed of the fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid's potential energy". When fluid flows through a leak path of a smaller diameter than the system, a resulting increase in the velocity at the point of convergenge occurs and is simultaneously coupled with a decrease in the pressure within the leak path. This pressure reduction increases rotational shear within the leakage and initiates the bonding of SEALMAKER to the sidewalls of the leak path.

How Does a Leak Path Seal

As SEALMAKER passes through a leak site it is exposed to shearing forces

Acceleration through the leak creates instability at the molecular level

Rotational forces amplify, embedding solid particles onto the sidewall while velocity increases

At critical velocity fibrillation of the the individual particles occurs

Fibrillation occurs creating a permanent seal that will hold pressure from all directions.

I

Mechanical Engineering Services

Altra CAD a full service product development firm. We specialize In SolidWorks design, prototype, 3D scanning, 3D printing, collaborating on patent drawings, and all the way to setting up manufacturing. Our experienced mechanical designers provide tailored product development services.

Get a consultation today to learn about each phase of product development services. Call us today and we would be glad to discuss all your product needs.

What We Do:

CNC Machining

3D Printing

Vacuum Casting

Rapid Tooling

Sheet Metal Prototyping

Aluminium Extrusion

Let’s Talk About Your Project Needs

See how our innovative engineering services can bring value to your project.